Heat transfer solutions for corrosive fluids

Corrosion resistant and highly conductive

Cost efficient

Tailored to your process

Heat transfer solutions for corrosive fluid processing

A variety of industrial processes involve the handling and processing of highly corrosive fluids. Examples include the production of chemicals or pulp and paper. Depending on process requirements, heat exchangers are used to either heat, cool, evaporate or condense substances such as concentrated acids. These extreme conditions strongly limit the choice of applicable heat transfer materials.

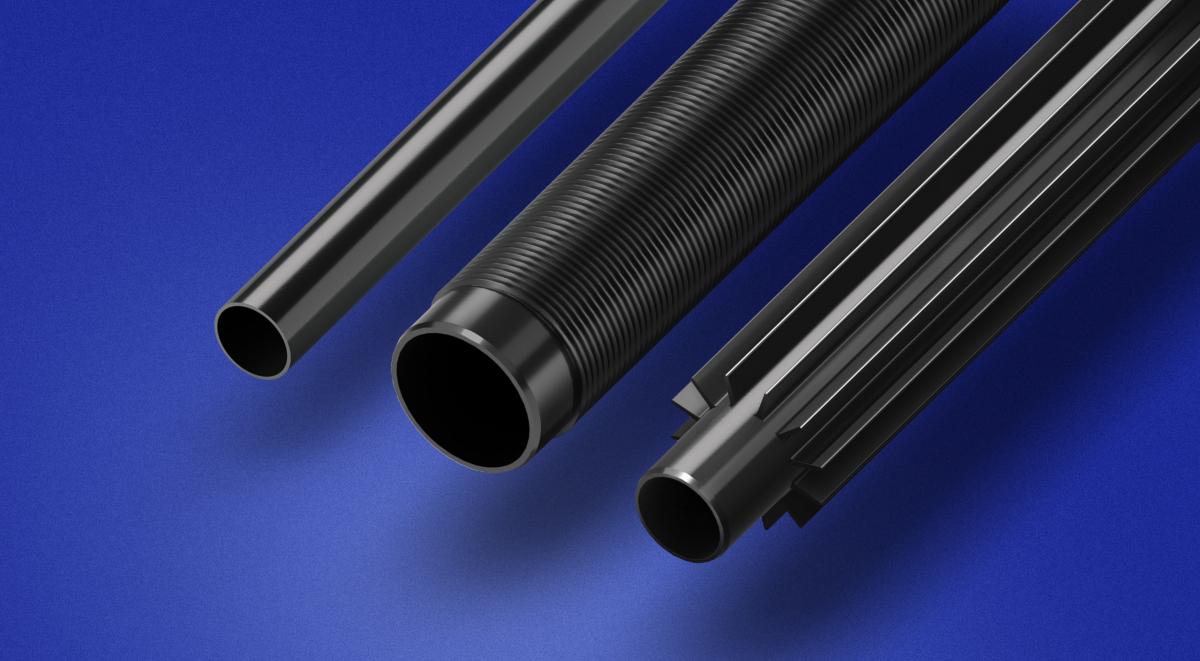

Our polymer based heat transfer solutions are ideally suited for such applications. They combine excellent corrosion resistance, heat conductivity, and design flexibility while reducing investment. Applications with fouling issues can benefit from the extremely smooth heat transfer surfaces of our solutions enabled by our high-end extrusion process.

Depending on customer need, we can supply either customized profiles and connection technology for seamless integration into existing designs or entire heat exchangers together with our global network of partners.