Heat transfer solutions for thermal water treatment

Reduced scale formation

Corrosion resistance

Lower environmental impact

Heat transfer solutions for thermal water treatment

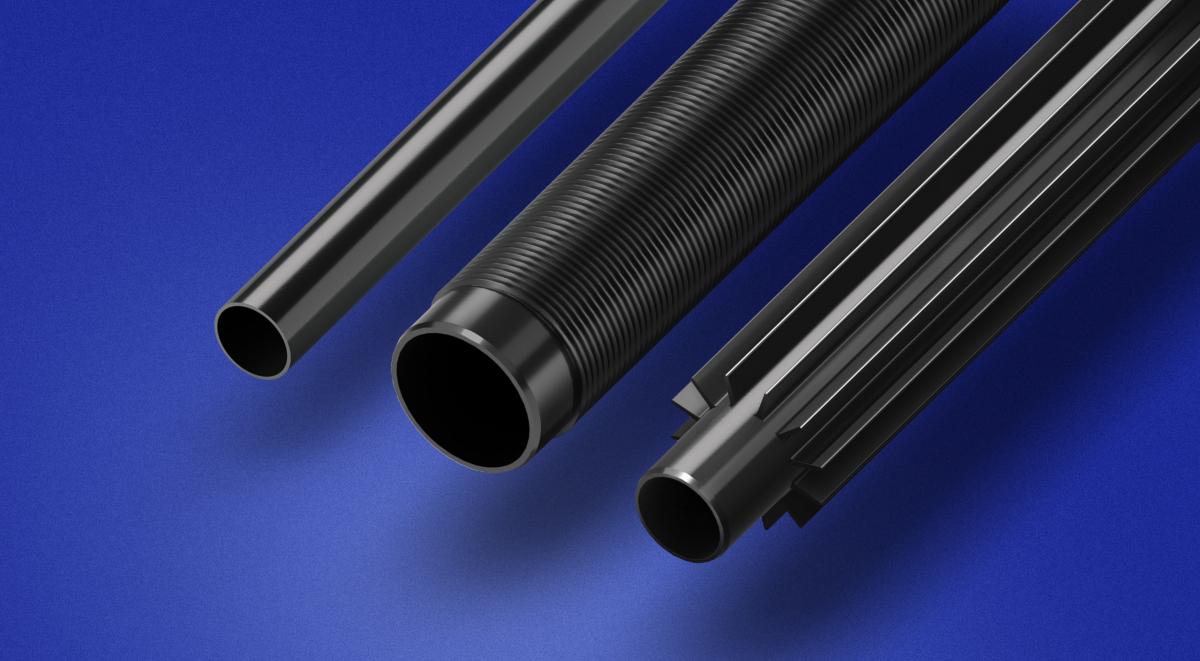

Thermal water treatment methods such as multi effect distillation are essential to ensure the global supply of potable and process water. They involve efficient evaporation of large quantities of different water qualities in order to produce clean distillate. Specific water components can lead to corrosion or formation of crystalline structures on heat transfer surfaces.

Our polymer based heat transfer materials are a natural fit to these challenging process conditions. Their excellent heat conductivity together with resistance to corrosion and scaling enables realiable plant operation. Furthermore, they are approved for use in potable water application under the German standard (KTW).

Depending on your needs, we can supply either customized profiles and connection technology for seamless integration into existing designs or entire heat exchangers together with our global network of partners.