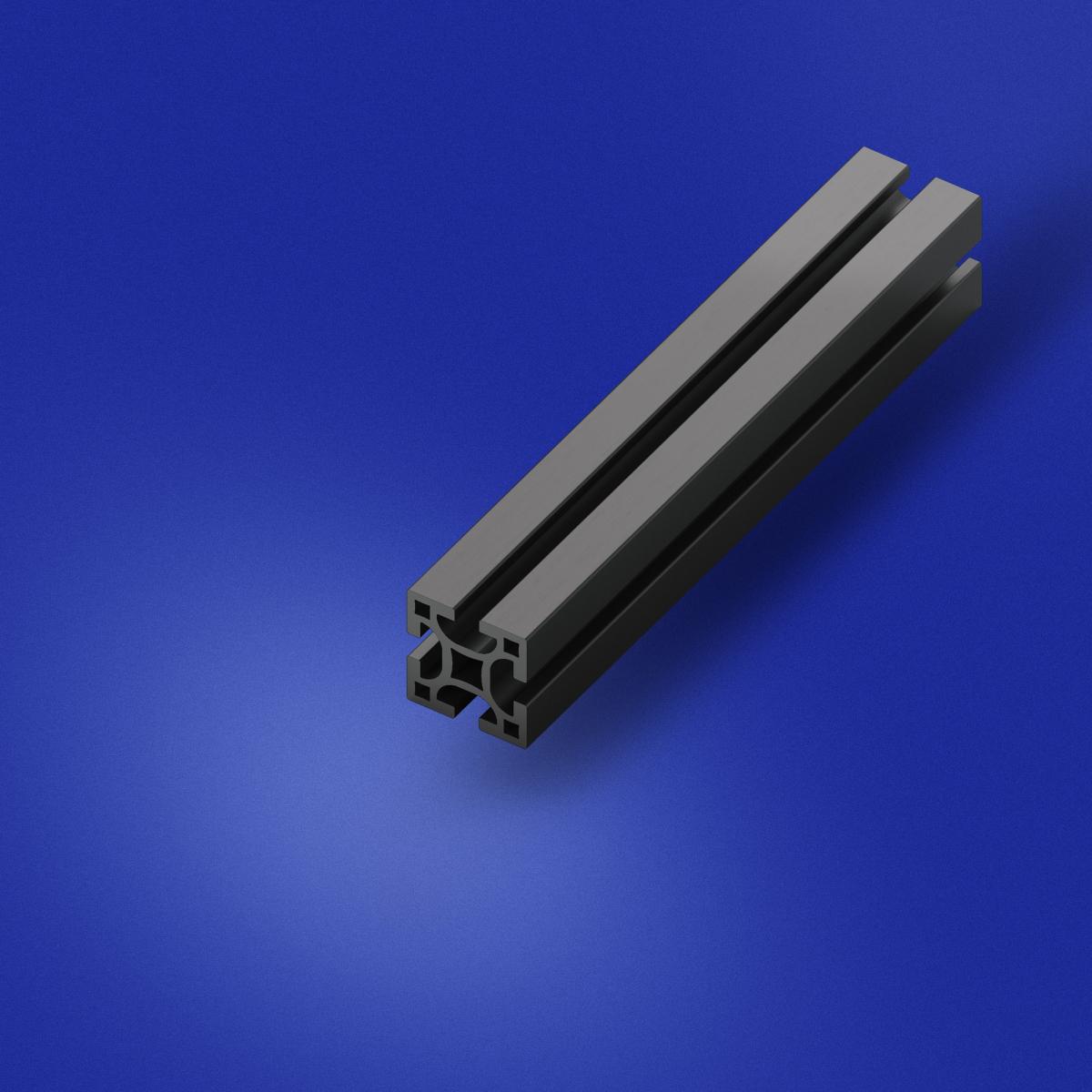

Reinforcement: the potential of fibre-reinforced plastics

Plastics, especially engineering plastics and high-performance plastics, can be reinforced with fillers, e.g. glass fibres, carbon fibres, minerals, or other reinforcing agents: Glass fibres, carbon fibres, minerals, or other reinforcing agents. These fillers give the material improved properties.Fibre-reinforced thermoplastics offer advantages for various applications in different industries. Improved mechanical properties through fibres such as glass, carbon or aramid fibres increase the strength, stiffness, and impact resistance of thermoplastics.

Advantages of fibre-reinforced plastic profiles:

- Lower weight: thanks to improved properties, products can be designed with thinner walls

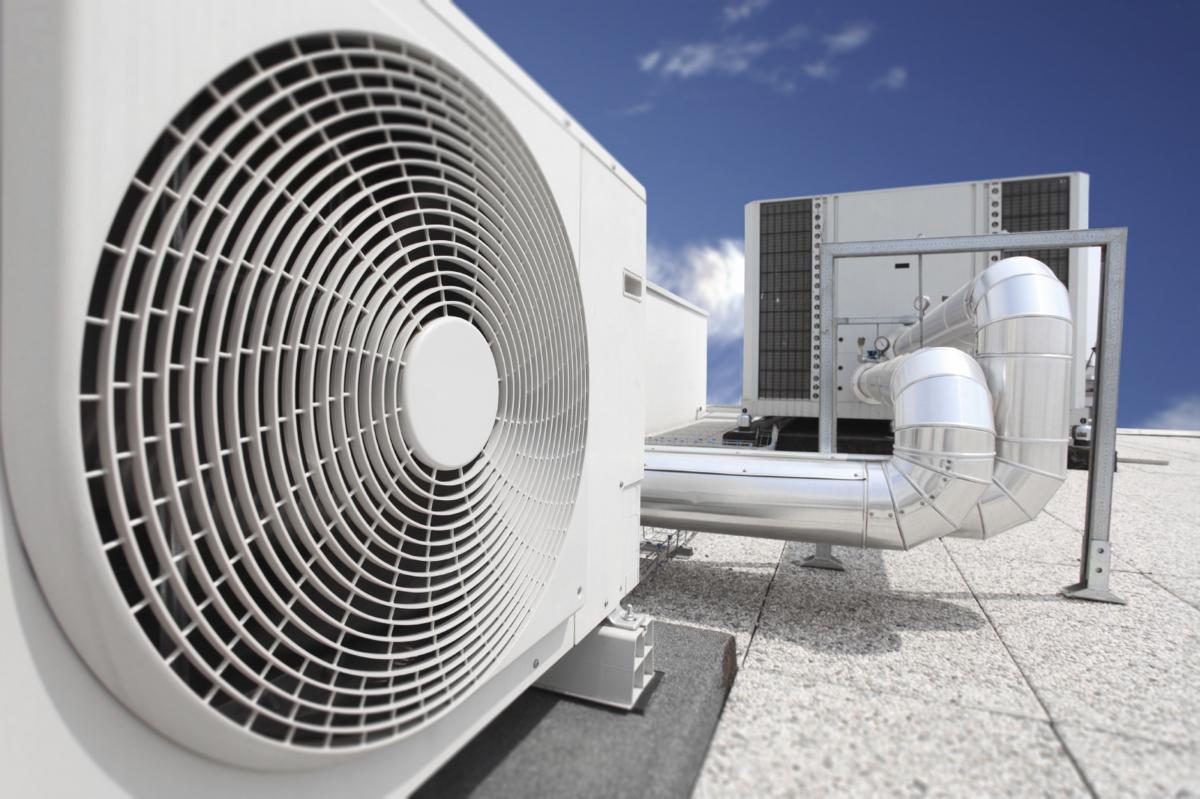

- Corrosion resistance: ideal for harsh environments and very good corrosion and chemical resistanc

- Design: fibre-reinforced plastic profiles can be designed to be more complex, stronger, and more durable

- High fatigue resistance: reinforced plastic profiles are excellent at withstanding stress over a long period of time. In particular, relaxation and retardation effects (yielding) are greatly minimised.

- Temperature stability: better thermal stability and strength over a wider temperature range

- Recyclability: thermoplastics can be re-melted

- Reduced creep: the addition of fibres reduces the tendency of the thermoplastic profile to deform under sustained stress (creep). The long-term performance of the material under load is improved

- Optimised thermal conductivity through carbon fibres or other thermally conductive fillers

Optimise your cost-benefit with filled plastic profiles:

Fibre-reinforced thermoplastic profiles lead to savings thanks to their superior durability and wide range of possible applications.

Not only in terms of material usage, but also over the entire life cycle of the product, filled plastics are ideal for numerous applications as they combine performance, weight and durability in a balanced way.

These advantages make fibre-reinforced thermoplastics an attractive choice for everything from consumer goods to critical aerospace components.

Reference project: fibre-reinforced plastic profiles for the GORE® Mercury Control System

Working with W. L. Gore & Associates, our engineers have developed fibre-reinforced plastic profiles for the GORE® Mercury Control System that display the same chemical, thermal and mechanical resistance as the original metal alloy components, but are easier to assemble and adapt.