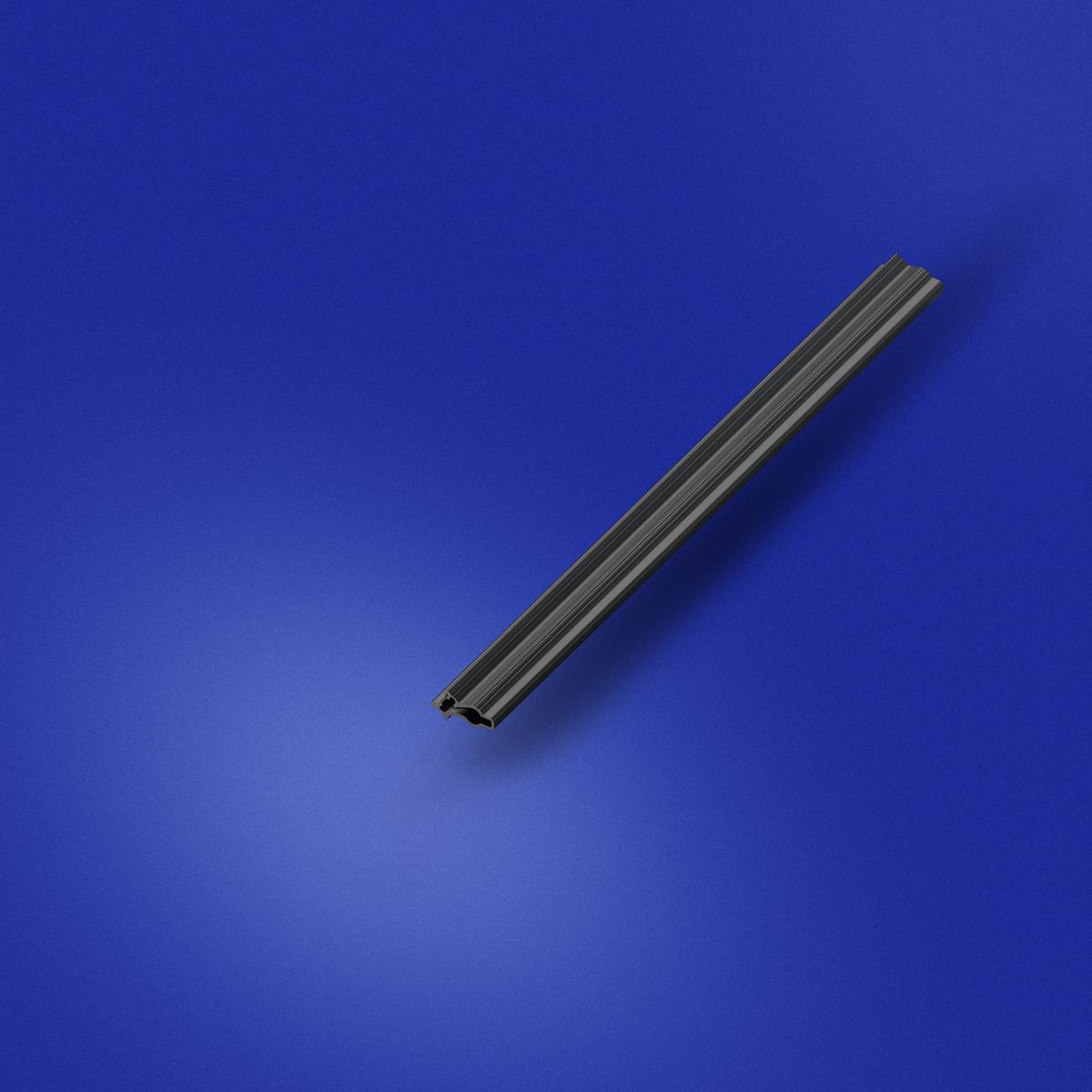

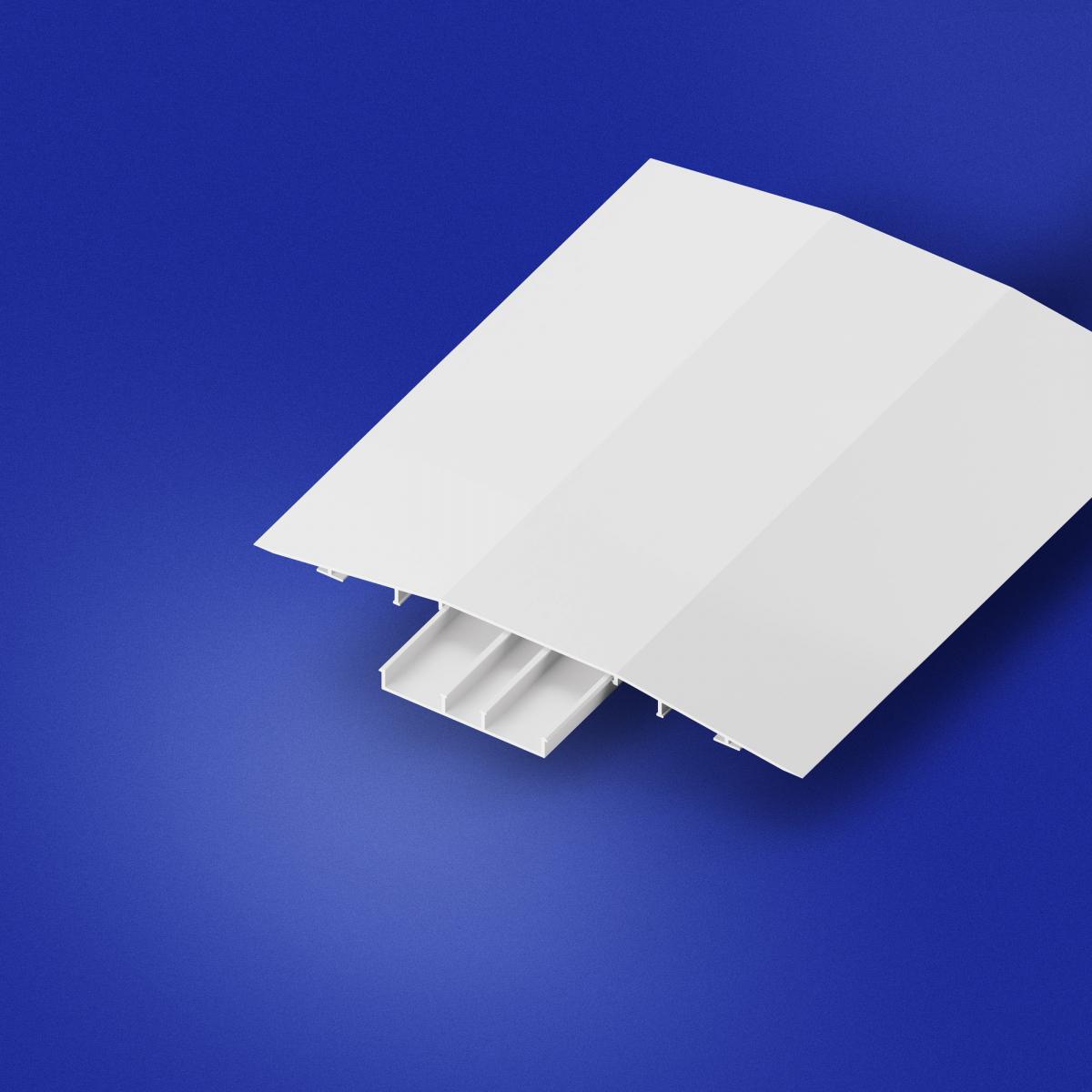

Pioneering Pultrusion Profiles

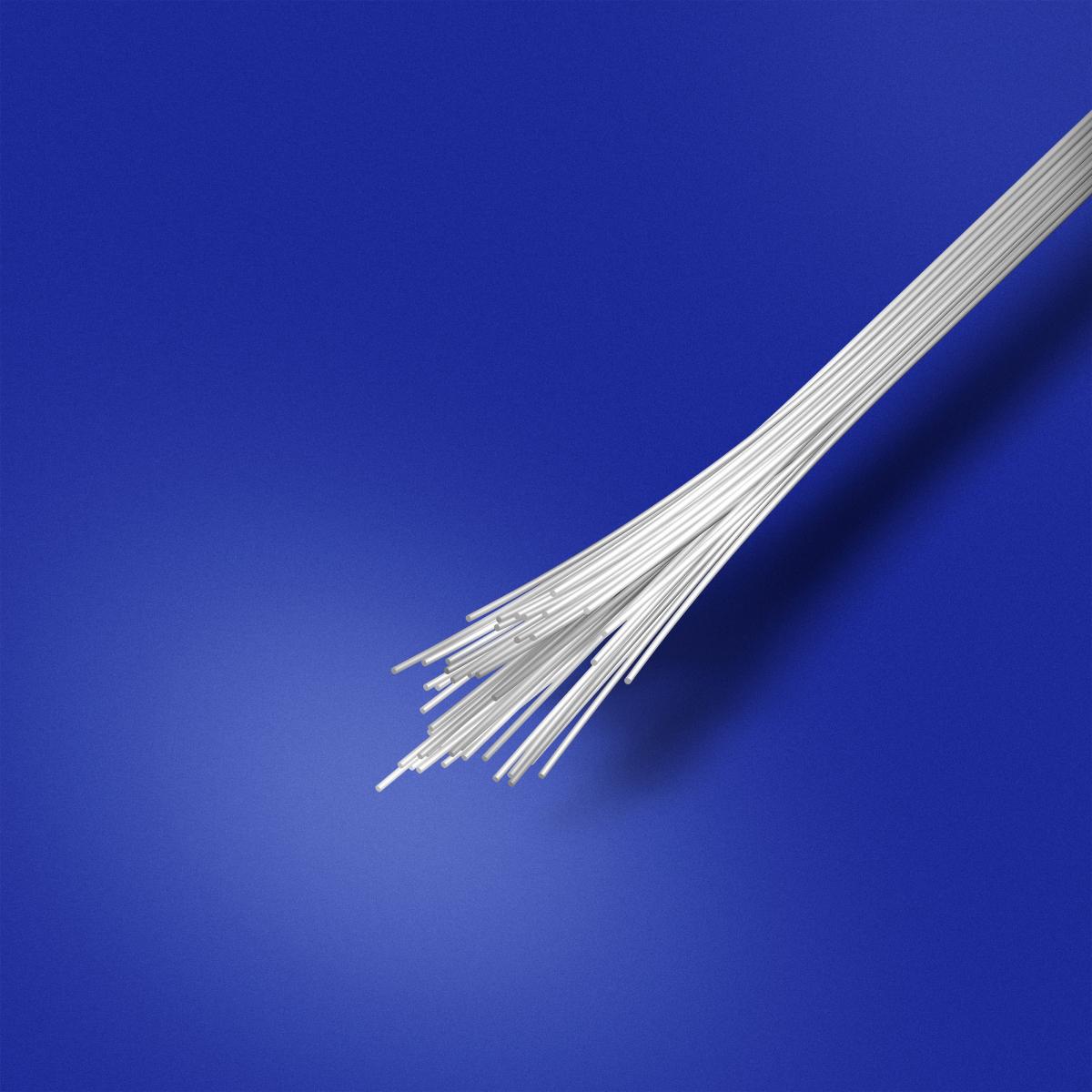

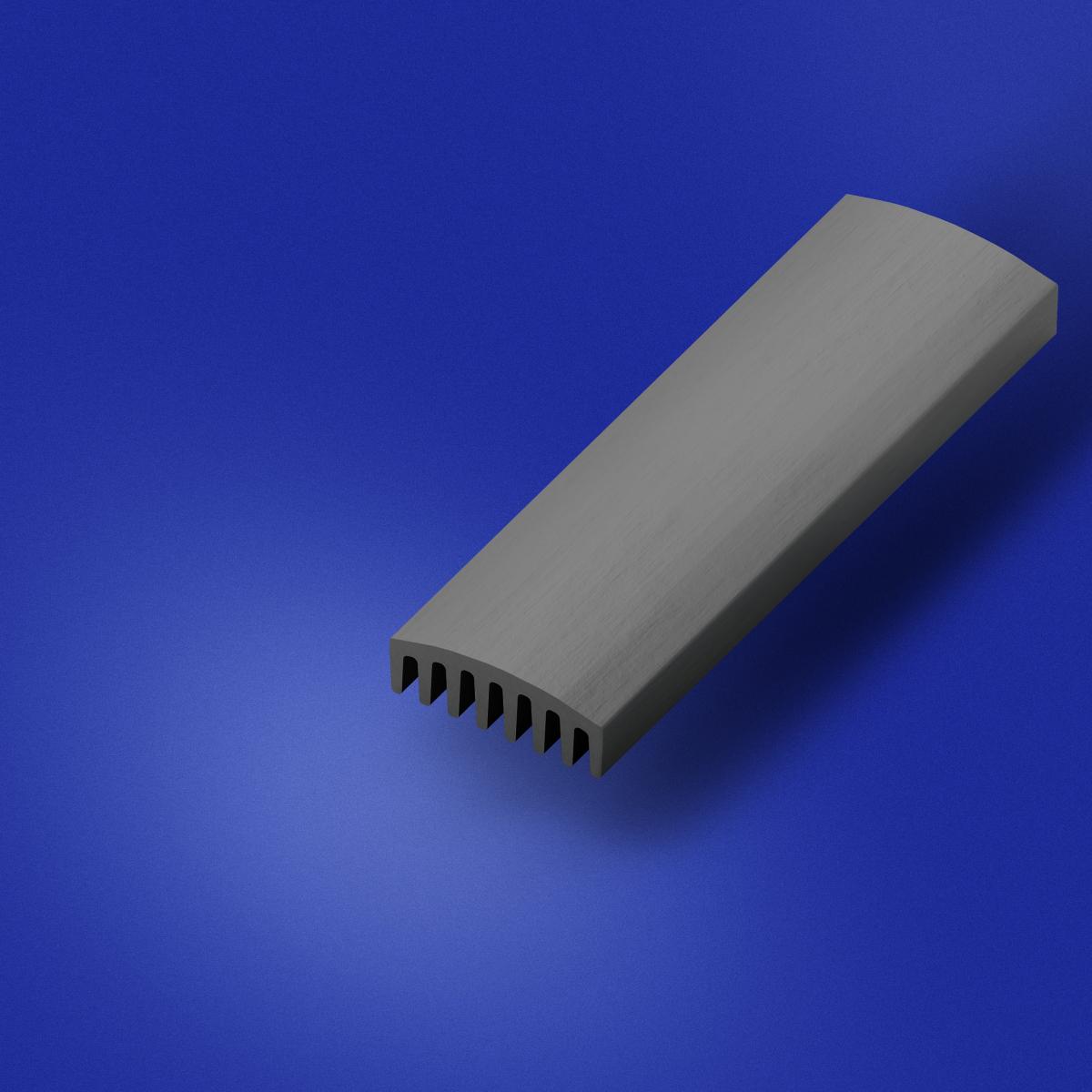

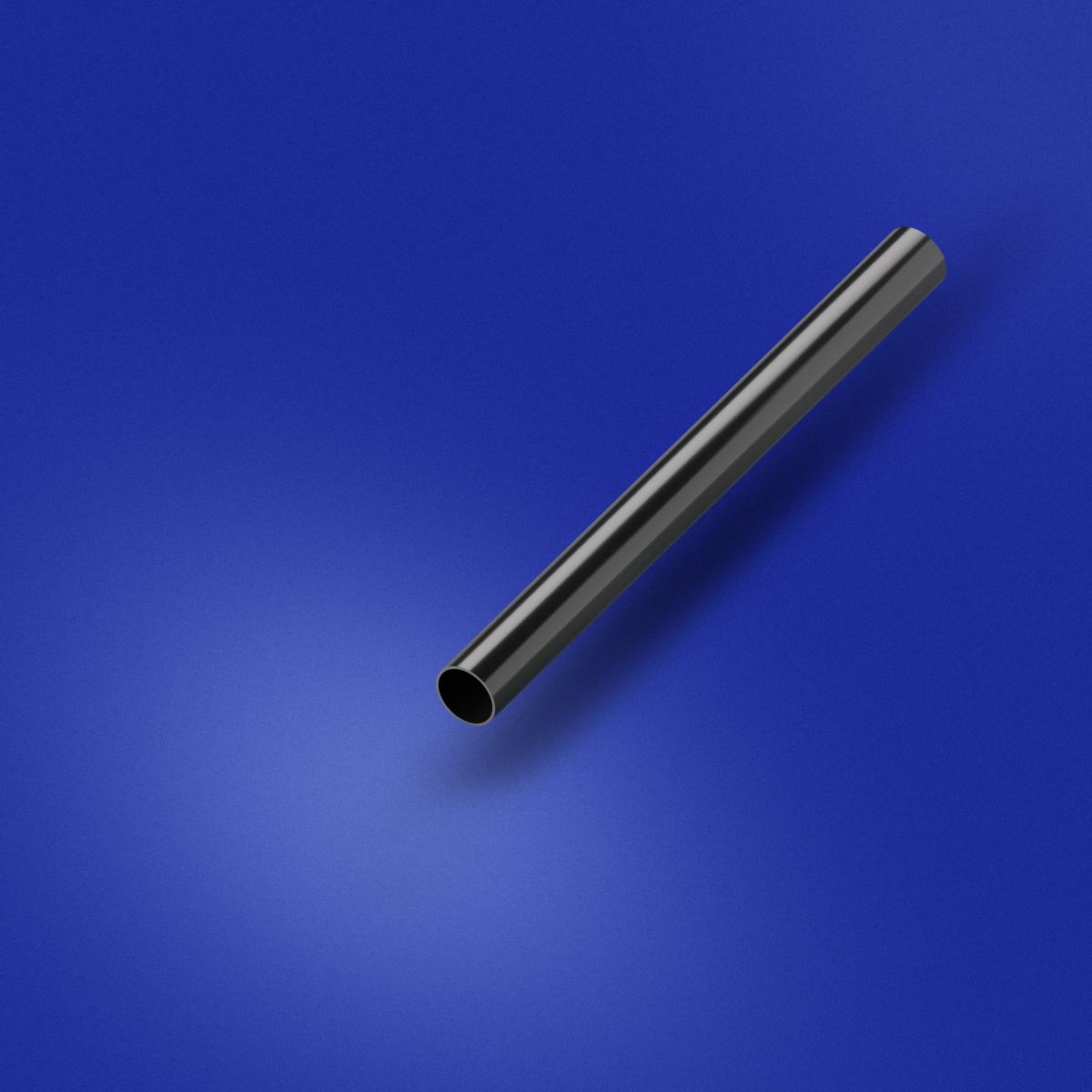

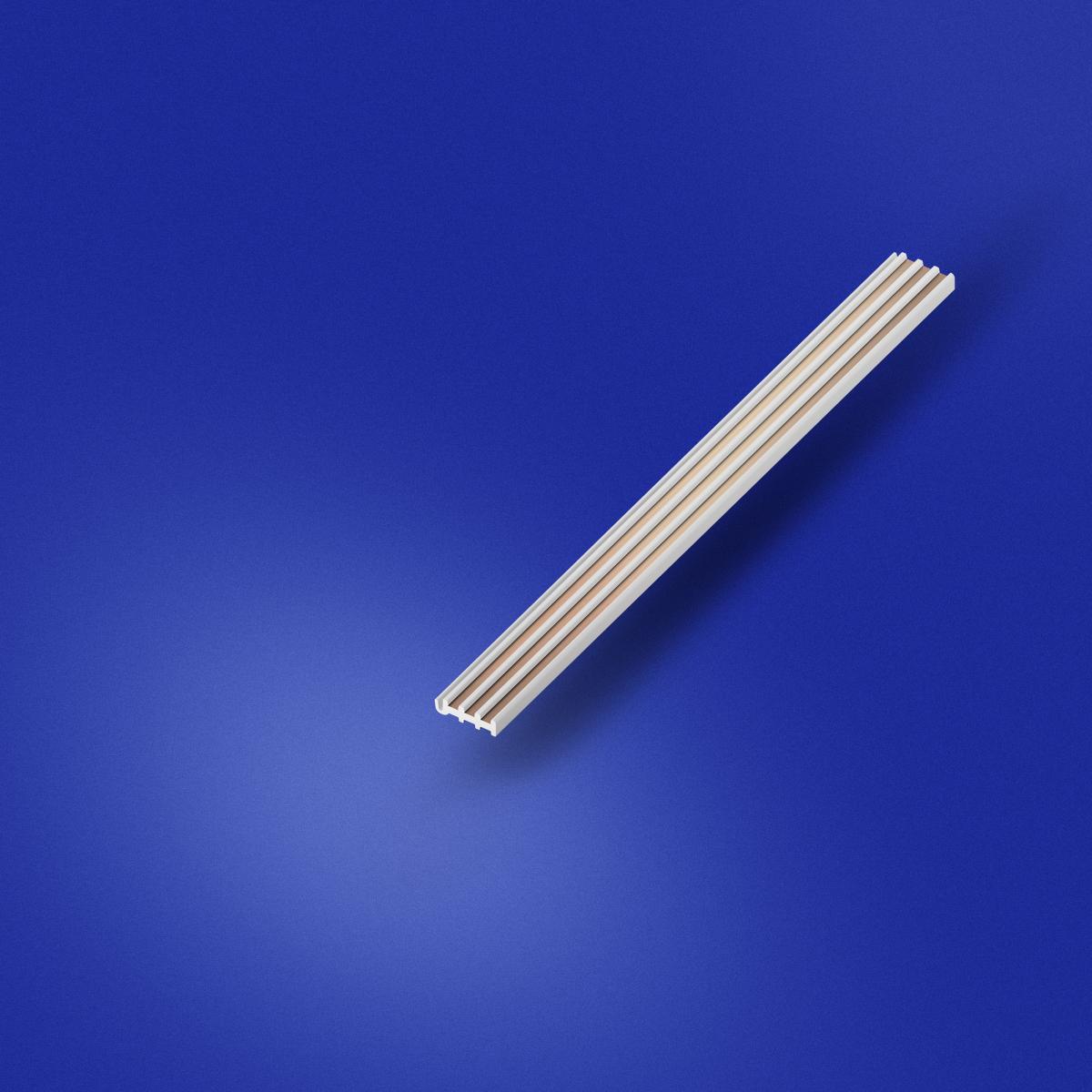

Continuous glass fiber profiles

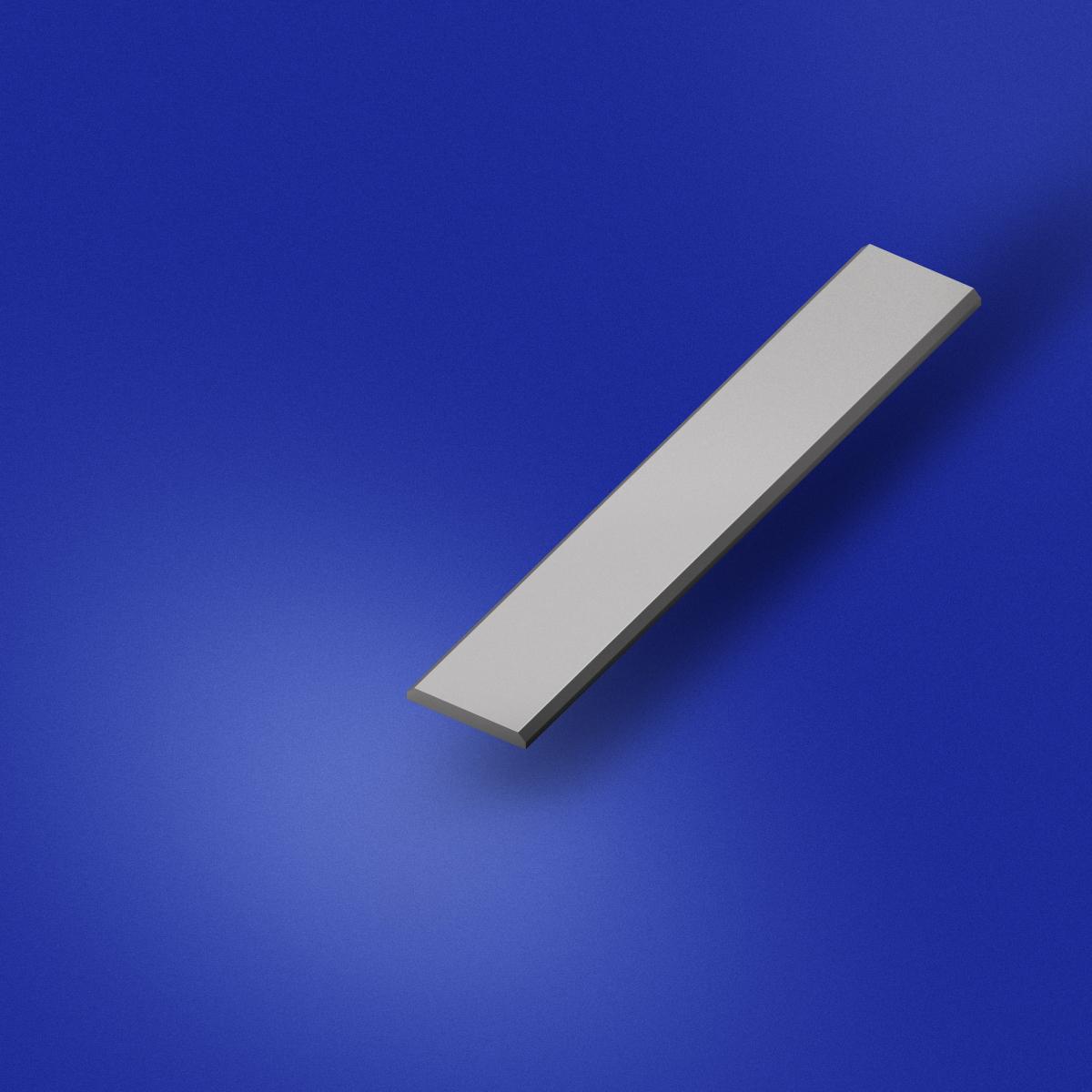

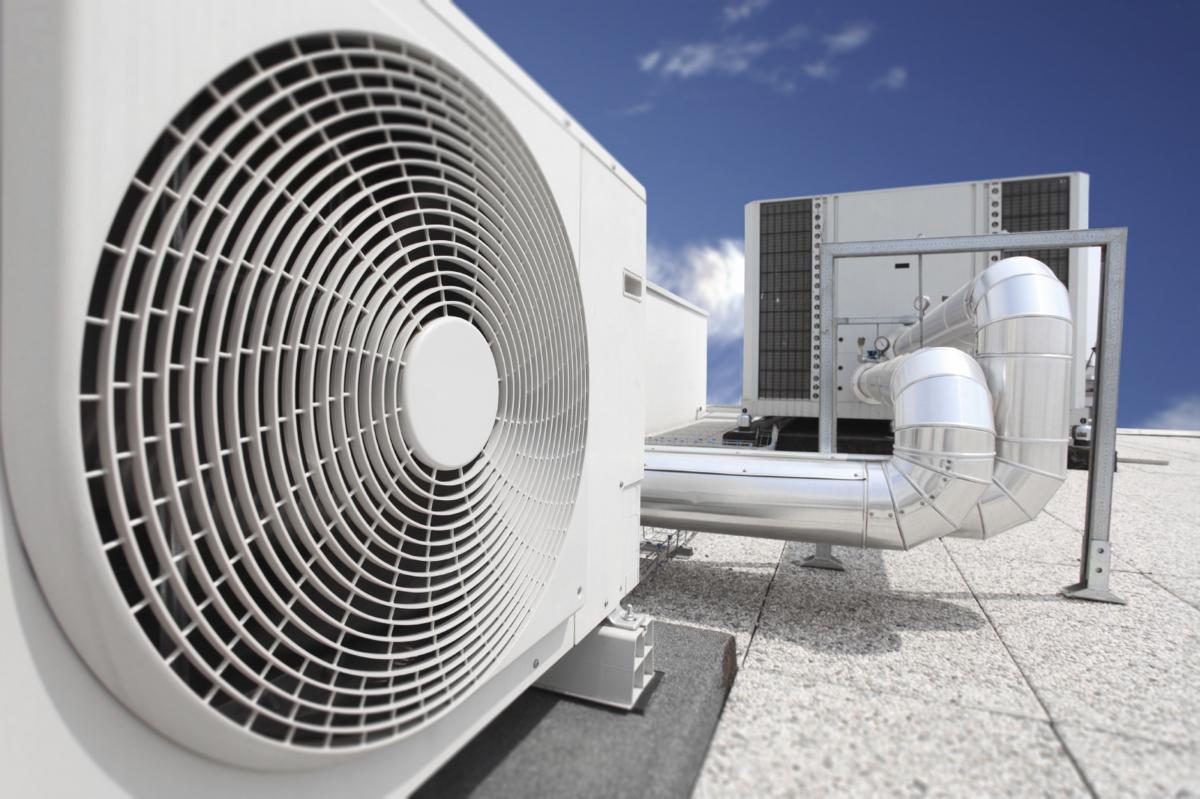

High-strength structural parts: strength meets sustainability

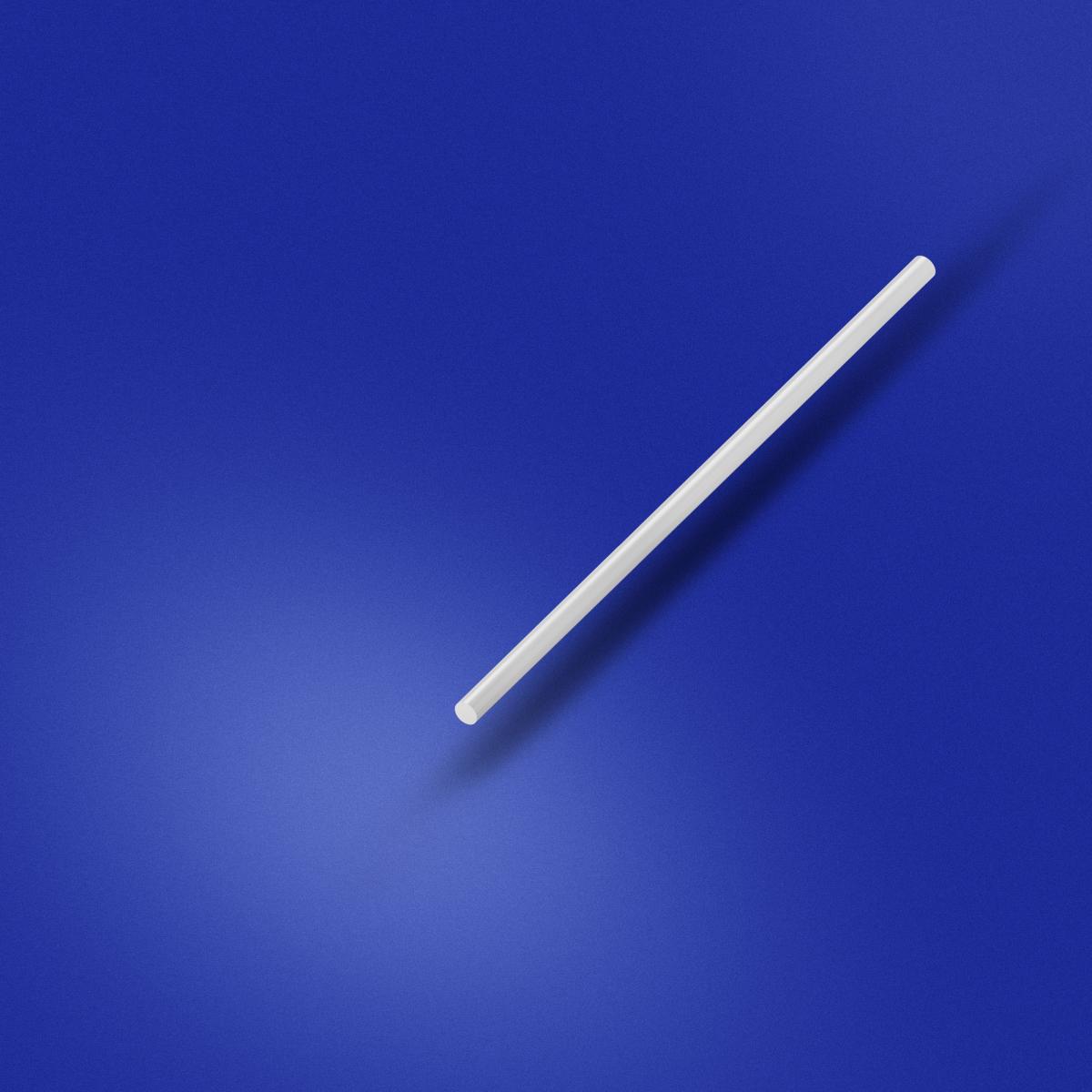

Pultrusion is a continuous process in which endless fibres are impregnated with a thermoplastic matrix material and drawn through a contouring tool. We currently use glass fibres surrounded by polyamide 6. Expansion to other thermoplastics is currently under development.

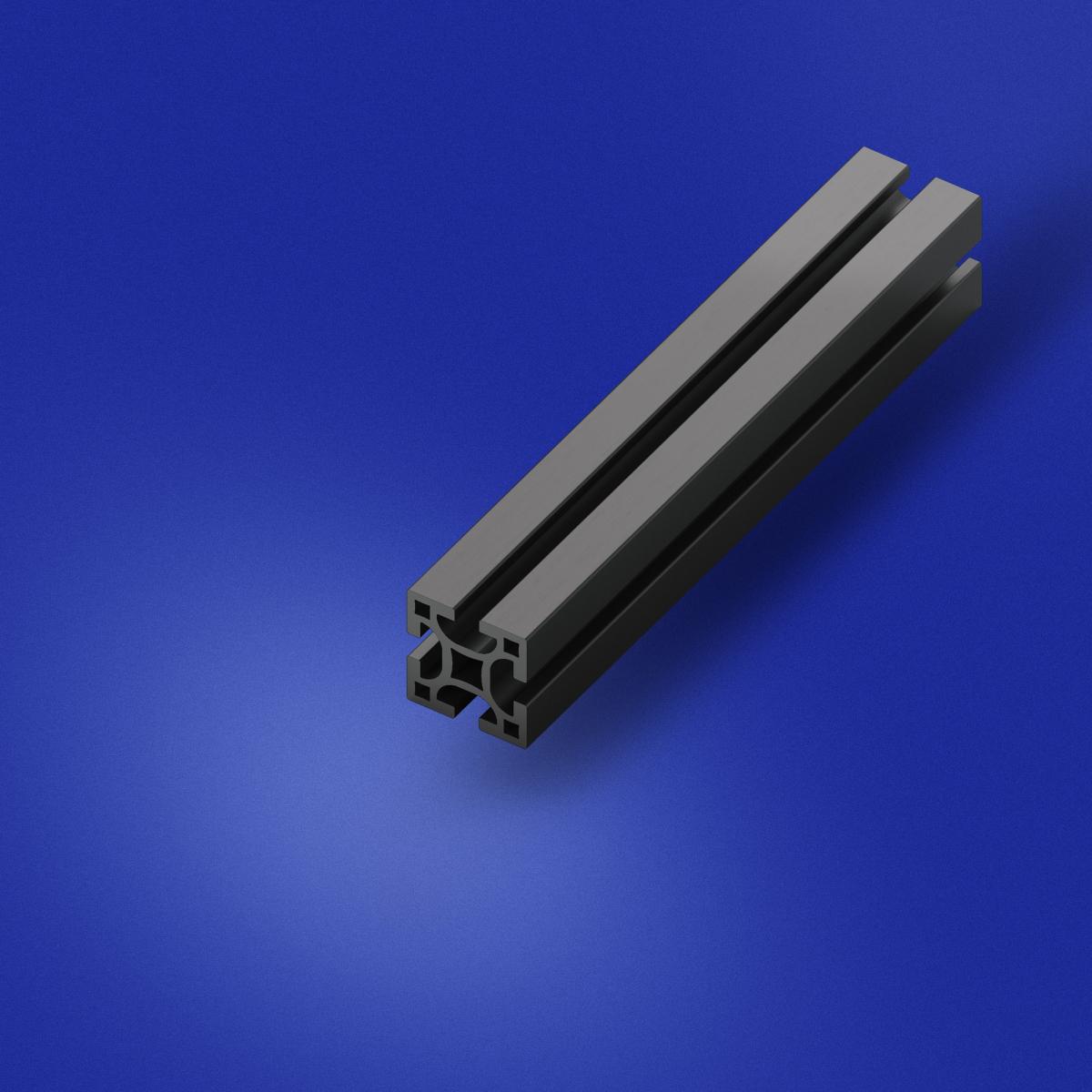

Improved mechanical properties

Find out how the performance of our pultrusion profiles can optimise your product. The high rigidity combined with low weight and material flexibility open up new design possibilities.

In the functional test, our pultrusion profile impresses with its flexural strength. At approx. 700 MPa, we achieve highest strength values.

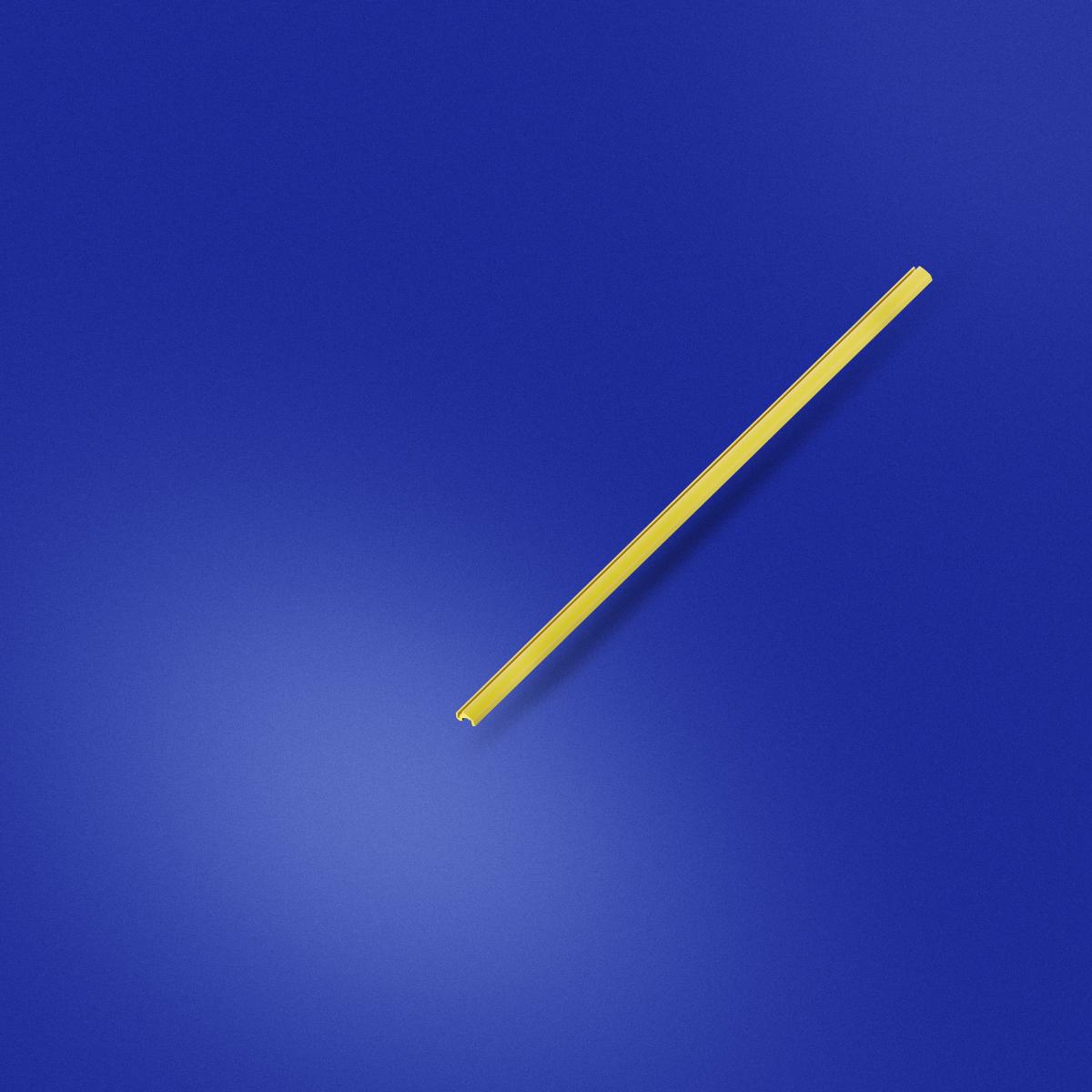

Benefits

- Weldable

- Thermally reformable

- Recyclable

- Light-weight solution

- Resistant to a wide range of chemicals

- Wide range of operating temperature

- Inserts for injection moulded or pressed components

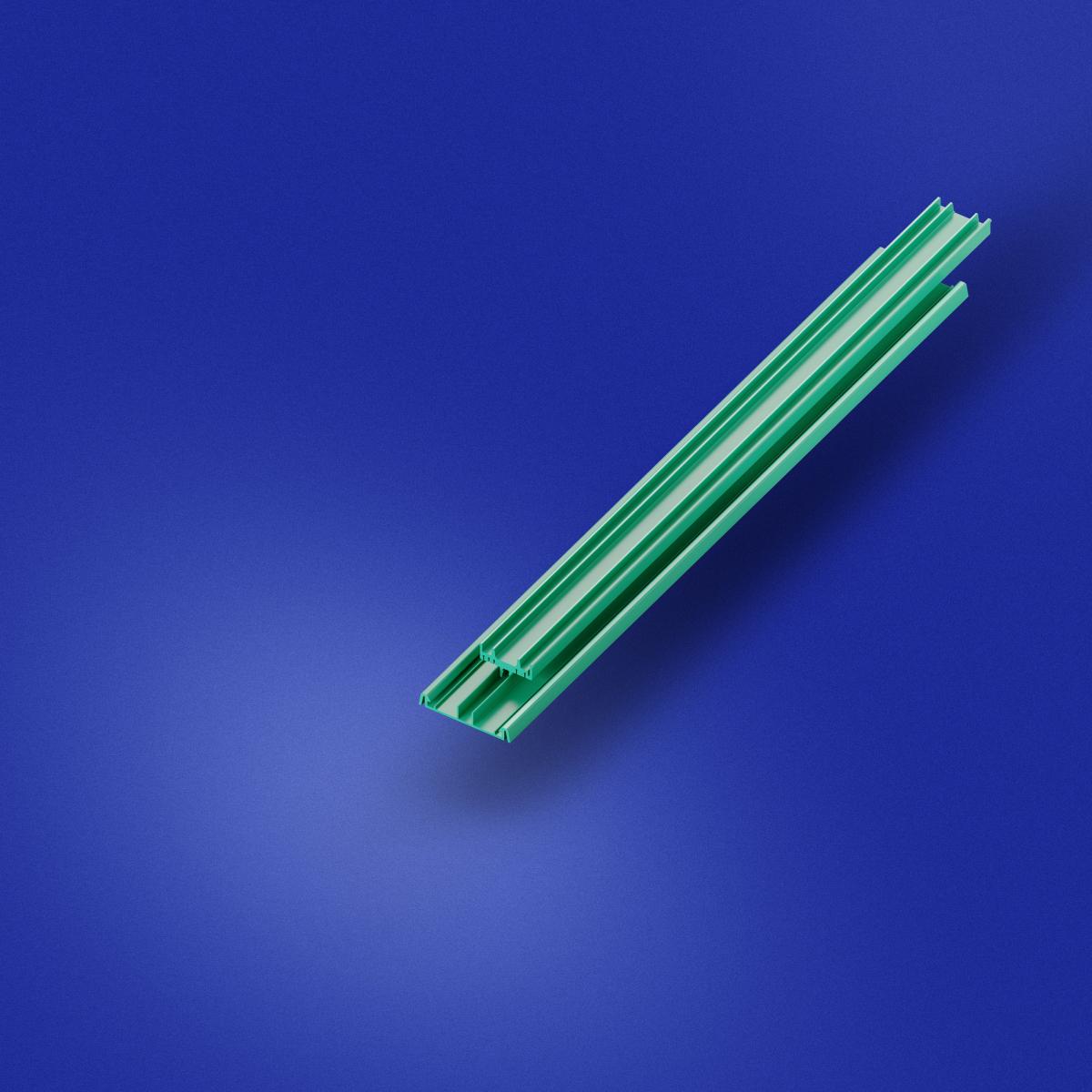

Further processing of pultruded profiles

Pultruded thermoplastic profiles can be further processed in many ways to optimise and reinforce your product:

Weld, insert, overmould or thermoform.