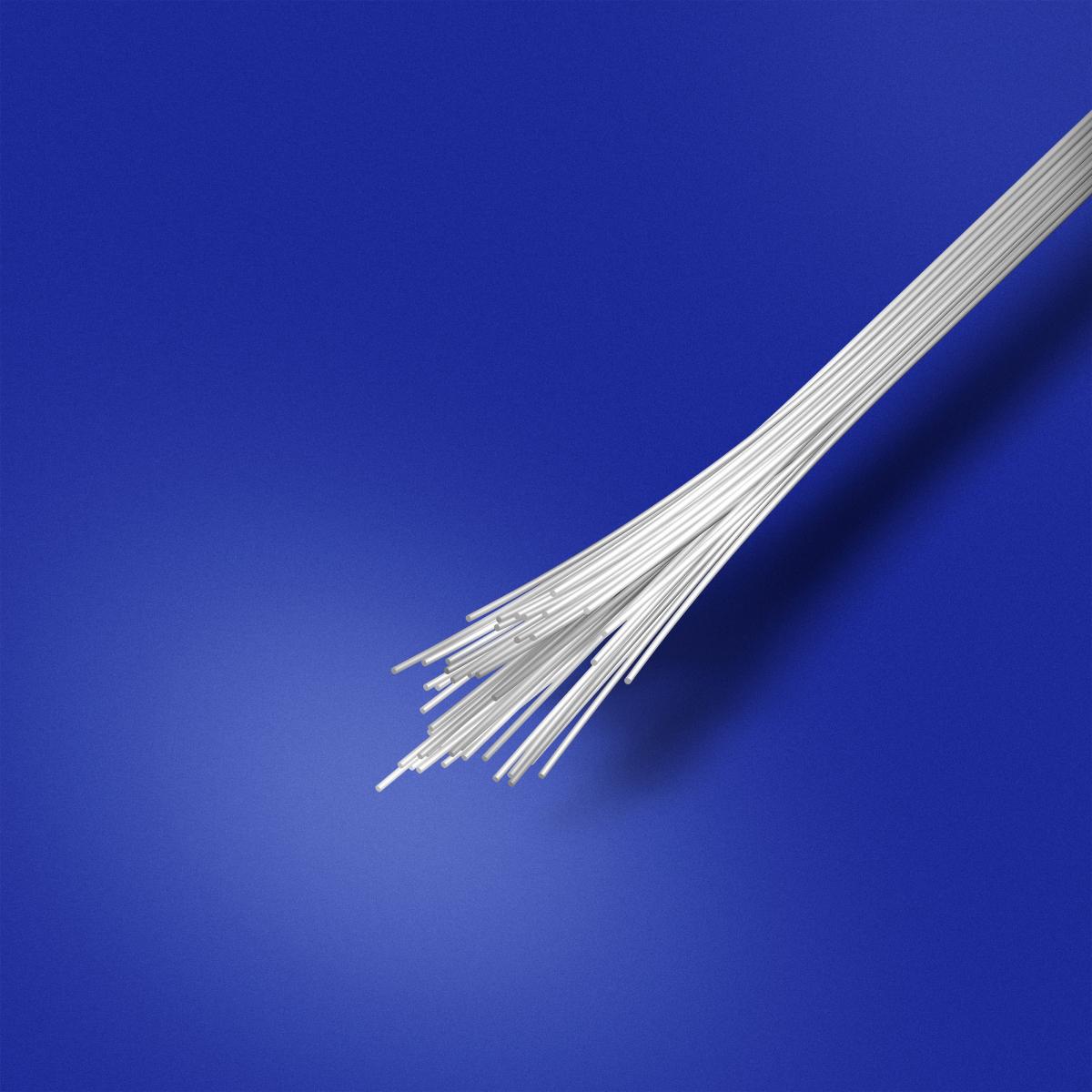

High-performance plastic mandrels for hose cores

In-built flexibility

Mandrels, used in the production of hoses, need to have a certain degree of flexibility so that they can be rolled with the hose itself. Our plastic mandrels, made from the technical plastic polyamide 6, deliver a flexible solution that can be custom-made to suit your production needs.

Cavity-free surface

To ensure the quality of the industrial hoses, the surface of the mandrel must be cavity-free. Our high-precision extrusion method makes it possible to produce absolutely cavity-free plastic mandrels for a smooth interior surface and high-quality finished product.

Heat-resistant

During the production process, the mandrel is subjected to high temperatures as the hose is baked or vulcanized around it. Our plastic profiles are temperature-resistant to further ensure the production of cavity-free mandrels.

Plastic mandrels for hose core production

During the production of industrial hoses, the hose is built up layer by layer on specially produced mandrels and then baked or vulcanized. To produce a high-quality finished product, the mandrels must be flexible, heat-resistant and cavity-free to ensure that the hose has the desired form once ready.

Our plastic mandrels, used in this hose core production process, are made from a temperature-resistant and flexible technical plastic, tailored to your production needs. Our high quality surface helps you to meet your performance requirements.