Plastic profiles for corrosion-resistance

Corrosion resistance

High stability

Complete systems from one supplier

Thermoplastics: a mature alternative to metal, and its equal

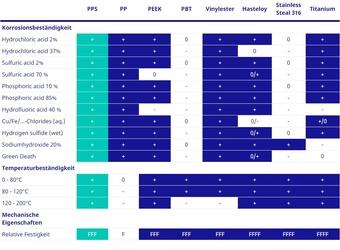

High-alloy metals have long been regarded as the material of choice for applications in aggressive environments, such as flue gas cleaning. Thermoplastics such as polyphenylene sulphide (PPS) are a modern, high-performance solution that is in no way inferior to the metals commonly used for applications subject to high chemical, thermal and mechanical stresses. PPS is notable for its very high resistance to chemicals and heat distortion, and for its high rigidity. It thereby satisfies the highest requirements for corrosion resistance and stability.

As a material for frame systems in flue gas applications, PPS offers compelling advantages over high-alloy metal, owing in particular to its superior facility for processing and its scope for adaptation of profile and connecting elements manufactured from engineering plastics. Further processing of alloyed metal components, such as the drilling of holes for the addition of socket or threaded joints during assembly, is far from straightforward. By contrast, plastic profiles can be adapted to changing requirements without their corrosion resistance or stability being impaired.

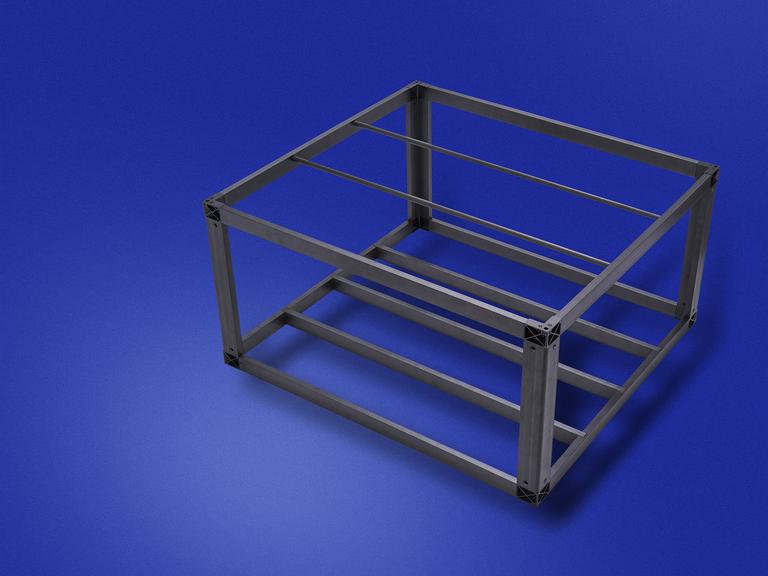

The manufacture of both load-bearing profiles and their connecting elements from thermoplastics such as polyphenylene sulphide (PPS) enables modular frame systems to be achieved that meet the most demanding requirements for chemical and mechanical resistance, permanently and as a complete system.

Modular frame systems for the most demanding requirements

Employing a proven modular principle, Technoform develops custom frame systems for any flue gas application involving acid precipitation. Unlike high-alloy metal systems, Technoform's load-bearing profiles and fasteners are made of the same stable, acid-resistant material.

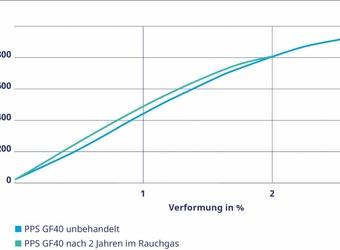

Since PPS is a high-strength solid material, it lends itself to flexible machining during assembly, unlike easily damaged alloys. The outstanding properties and durability of the plastic have been proven in long-term tests and in use in industry.

Case study: Thermoplastic replaces corrosion-resistant metal in a mercury filter at W. L. Gore & Associates

Thermoplastics such as polyphenylene sulphide (PPS) are in no way inferior to metals and even offer persuasive advantages – a fact which is often overlooked. We helped W. L. Gore & Associates to replace all their metal components with engineered plastic in the framing system of the GORE mercury filter.

Case study: polyphenylene sulphide PPS wins in long-term test at Frankfurt’s waste water treatment facility, Stadtentwässerung Frankfurt.

Components used in waste gas filter systems are exposed to high levels of chemical, thermal and mechanical stress. Unsuitable thermosets in this aggressive environment can have far-reaching consequences. This was also the experience of Frankfurt’s waste water treatment facility, Stadtentwässerung Frankfurt, for whom we conducted some extensive material tests and found a high-performance alternative to thermosets.

Decision-making aid for project managers: Which thermoplastic is suitable for applications in an aggressive environment?

Under extreme conditions, materials must reliably and permanently maintain their mechanical properties despite chemical and thermal stress. The challenge for project managers is to select the right material that meets all their requirements, while also offering the best value for money. We’ll support you in this and compare some common plastic and metal materials for you.