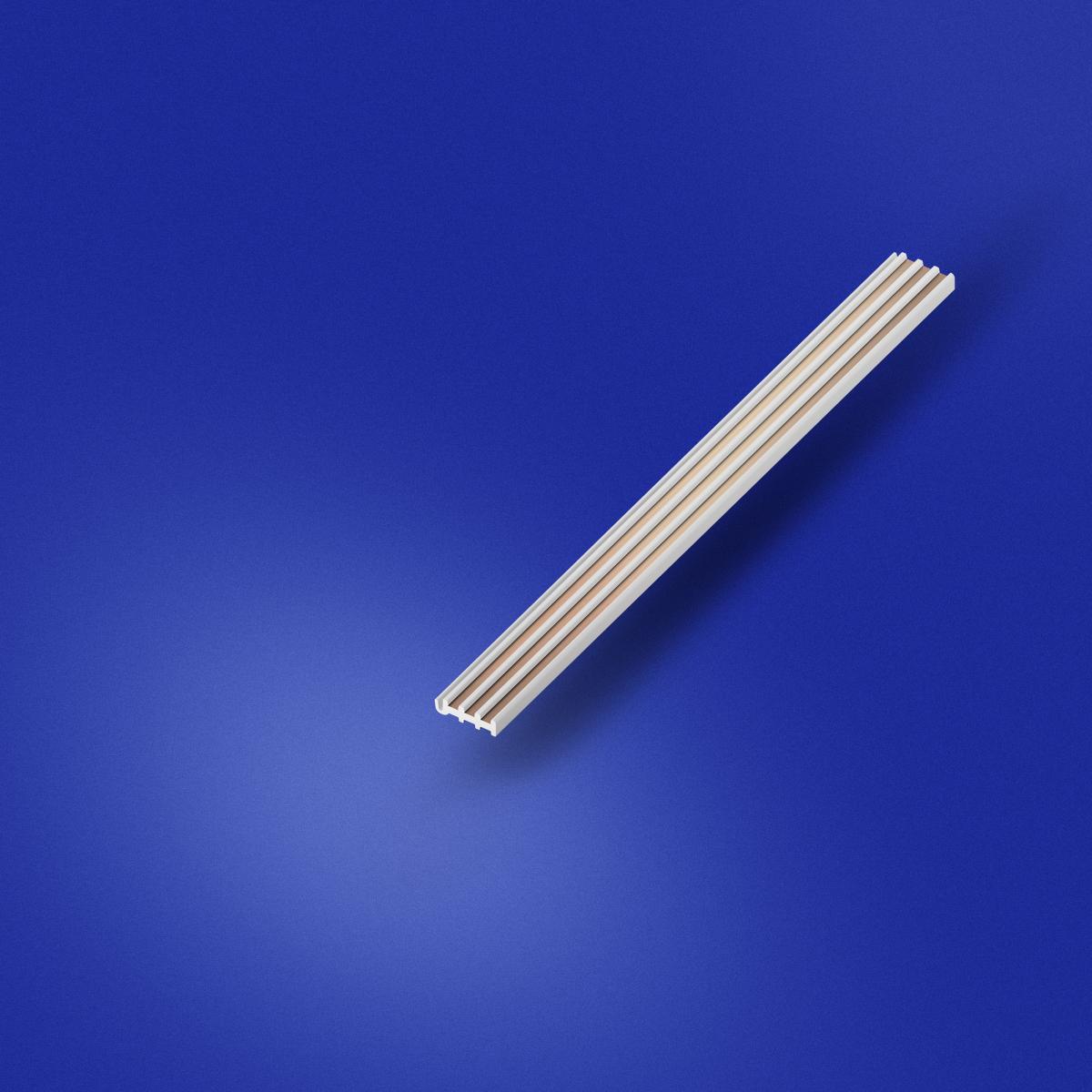

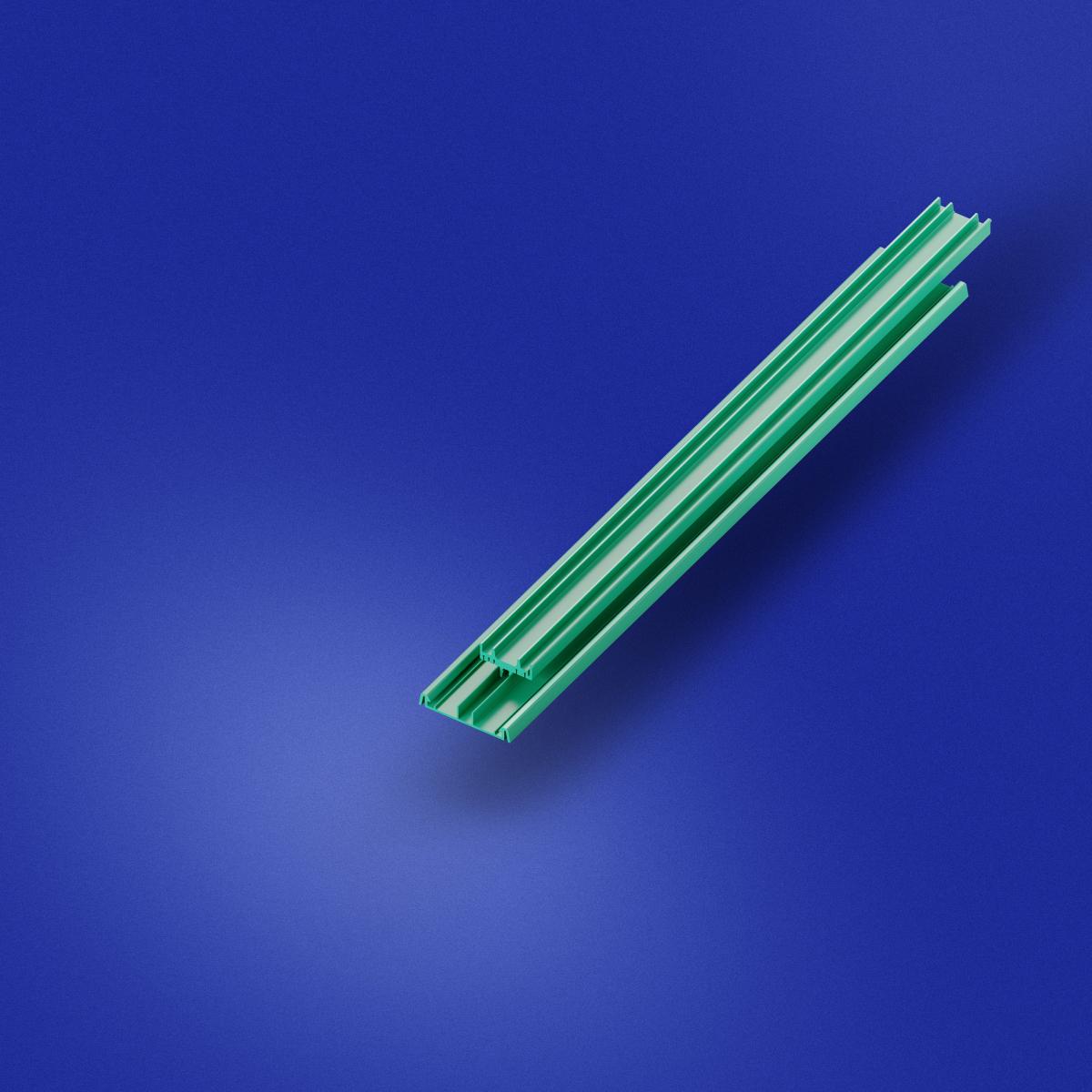

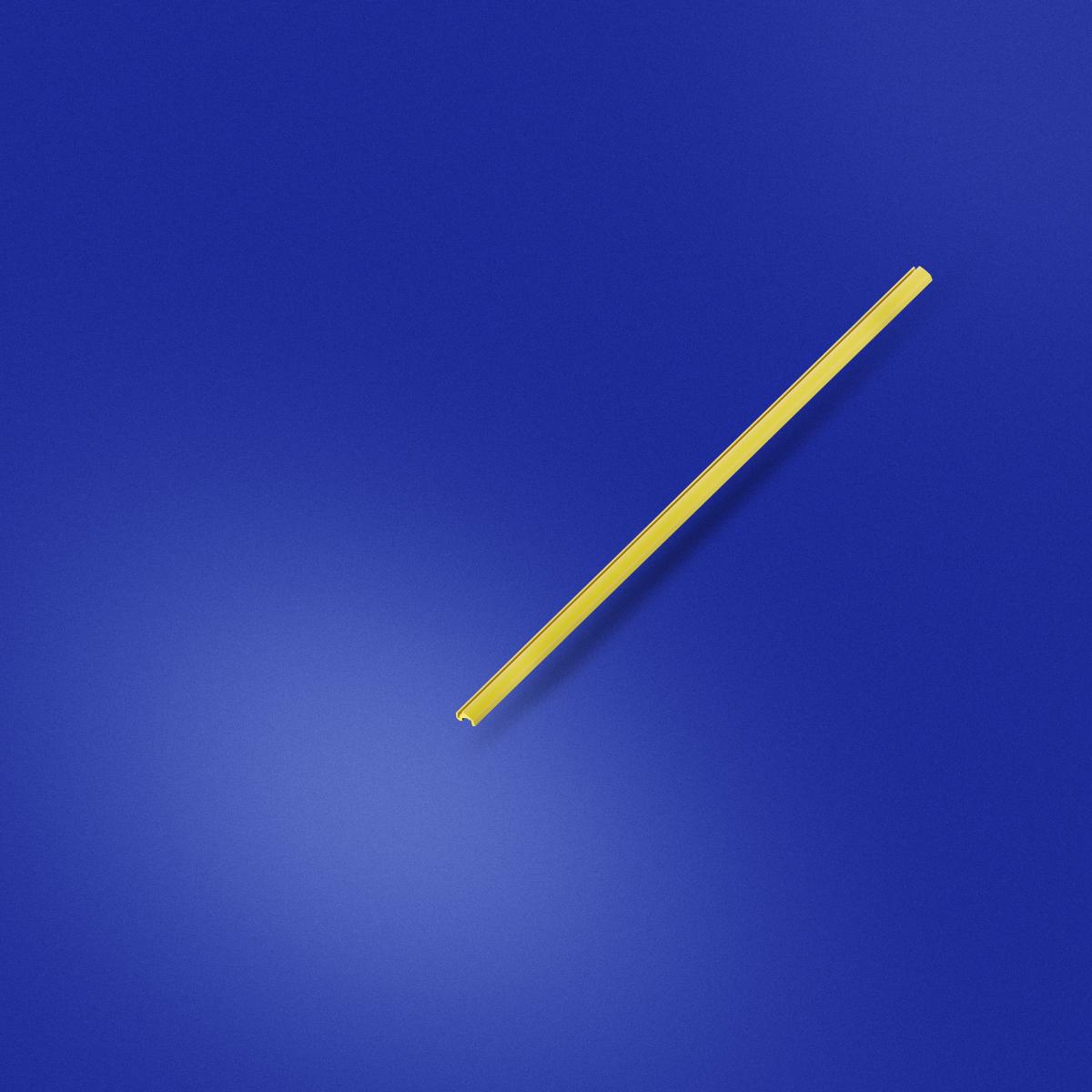

Plastic LED cooling element

Thermal conductivity and electrical insulation

High-performance materials

Replacing aluminum as a key material in heat management

Staying cool when the heat is on

LED lighting has taken the world by storm, reducing energy consumption, increasing longevity and allowing for new design concepts that were previously impossible. They do, however, require effective management of heat, as they get very hot during use. Thermoplastic profiles can both dissipate the heat they generate, whilst keeping them electrically insulated. That means less parts required for a lighting solution, resulting in more flexible design possibilities and easier production.

Thermoplastics are revolutionizing many applications. Where it was previously a complex and materially intensive process to design heat management solutions for LEDs, thermoplastics are replacing traditional metal-based products because of their many advantages. If you need a tailored LED cooling solution, we will work with you from start to finish to produce the high-end profiles that will complete your project.