Materials for aggressive environments: Polyphenylene sulfide wins in long-term test at Frankfurt’s wastewater treatment facility

Components are exposed to high levels of strain if they are used in exhaust gas purification filter systems. They must be resistant to acid and at the same time meet a range of mechanical requirements. If inappropriate materials are used, this can easily have far-reaching consequences.

This was also the past experience of Frankfurt’s wastewater treatment facility, Stadtentwässerung Frankfurt am Main (SEF). Together with Technoform, SEF therefore started to look for a suitable solution to reduce the amount of mercury in the activated carbon adsorber in its sewage sludge incineration plant. The material that did best in a long-term test was polyphenylene sulfide (PPS). Unlike the thermoset materials used until recently, it is a solid material with lower susceptibility to mechanical damage.

Heavy metals in sewage sludge incineration

Since the 1980s, sewage sludge from the Greater Frankfurt area has no longer been used in agriculture – as was once customary – but has been disposed of in the sludge dewatering and incineration plant. The plant comprises four incineration lines, where up to six tonnes of sewage sludge per hour is first dried and then incinerated.

The resulting flue gases contain heavy metals and pollutants that are removed in a complex process. They include mercury, a highly toxic heavy metal that spreads worldwide through wind and sea currents, is absorbed by animals and plants and also builds up in the human body. Studies have shown that modern technology can reduce mercury emissions by 85 per cent.

Reliable removal of mercury

SEF continuously upgrades and maintains its plant in order to meet the ever-increasing legal requirements, such as limits on mercury emissions. For the flue gas treatment, SEF installed an adsorber that works with sulfur-doped activated carbon. Both elemental and ionic mercury can thus be reliably separated from the flue gases. The ad-sorber consists of several modules. What is crucial here is the section systems that support the activated carbon. They need to meet three criteria: (1) mechanical robust-ness, so that they can bear the weight of the activated carbon, (2) heat resistance and (3) resistance to acid.

Schematic representation: The section system in the mercury filter carries the activated carbon and must meet high mechanical, thermal and chemical requirements.

Acid exhaust gases attack materials

In the past, SEF had opted for a pure stainless steel design, but realised after only a short time that condensates and acidic waste gases were very harmful to the material. They then assumed that thermoset could provide a remedy, as its base material, an unsaturated vinyl ester with glass fibres, is considered a guarantee for high mechanical resilience. Furthermore, its special coating of saturated vinyl ester is said to prevent acids from penetrating and damaging the base material. Regrettably, however, those materials proved to be equally problematic.

The problem:

Coated plastic is vulnerable

One major feature of components with a layered structure is that they combine the benefits of several different materials. Their downside is that any damage to the protective layer makes it permeable, and minor scratches can frequently appear in a sewage sludge incineration plant. This may occur, for instance, during inspections (carried out every two years) or when replacing the activated carbon (every four years). Whenever it happens, the support sections need to be removed and reinstalled. If damage is detected, the affected parts have to be either replaced or repaired, a process which is expensive and timeconsuming.

The aim:

To minimise risks through the use of solid material

To ensure the plant operates safely and maintenance-free, SEF has to use components made of robust materials that will survive even in aggressive environments. As coated materials meant that SEF had to carry out a large amount of maintenance, the company started to explore alternative options. SEF wanted to replace its thermosets with a solid material without any risk of surface damage impairing performance.

Daniel Adolph, Head of Operations at SEF.

Material specialists required

This is why SEF turned to Technoform, a company that specialises in plastics. Working together, we conducted long-term tests on several materials and combinations of materials which were suitable for an aggressive environment while also combining chemical, thermal and mechanical resistance.

The solution:

Finding the right material

Technoform specialises in the extrusion of thermoplastic sections. We supply finished plastic products for a variety of needs and applications. We also work in partnership on custom solutions in a wide range of industries, including electrical engineering, the automotive industry and mechanical engineering, to name but a few.

Together with SEF, we designed a scenario for both a lab test and a long-term test that would identify several materials which were suitable for the customer’s specific requirements. “Lab tests can never fully reflect the actual use within the plant,” says Dr Thorge Brünig, who manages the project at Technoform. “A long-term test in the actual environment was important, as it would put the materials through their paces – including any potential damage during installation and removal.

Practical testing of the materials

Three different challenging locations were chosen for the practical test of the selected materials in the sludge dewatering and incineration plant:

- one in the lower section of the plant where there is a build-up of acid condensates,

- one in the upper section where the gas enters the system and where temperature fluctuations occur,

and one in the middle section where conditions tend to vary.

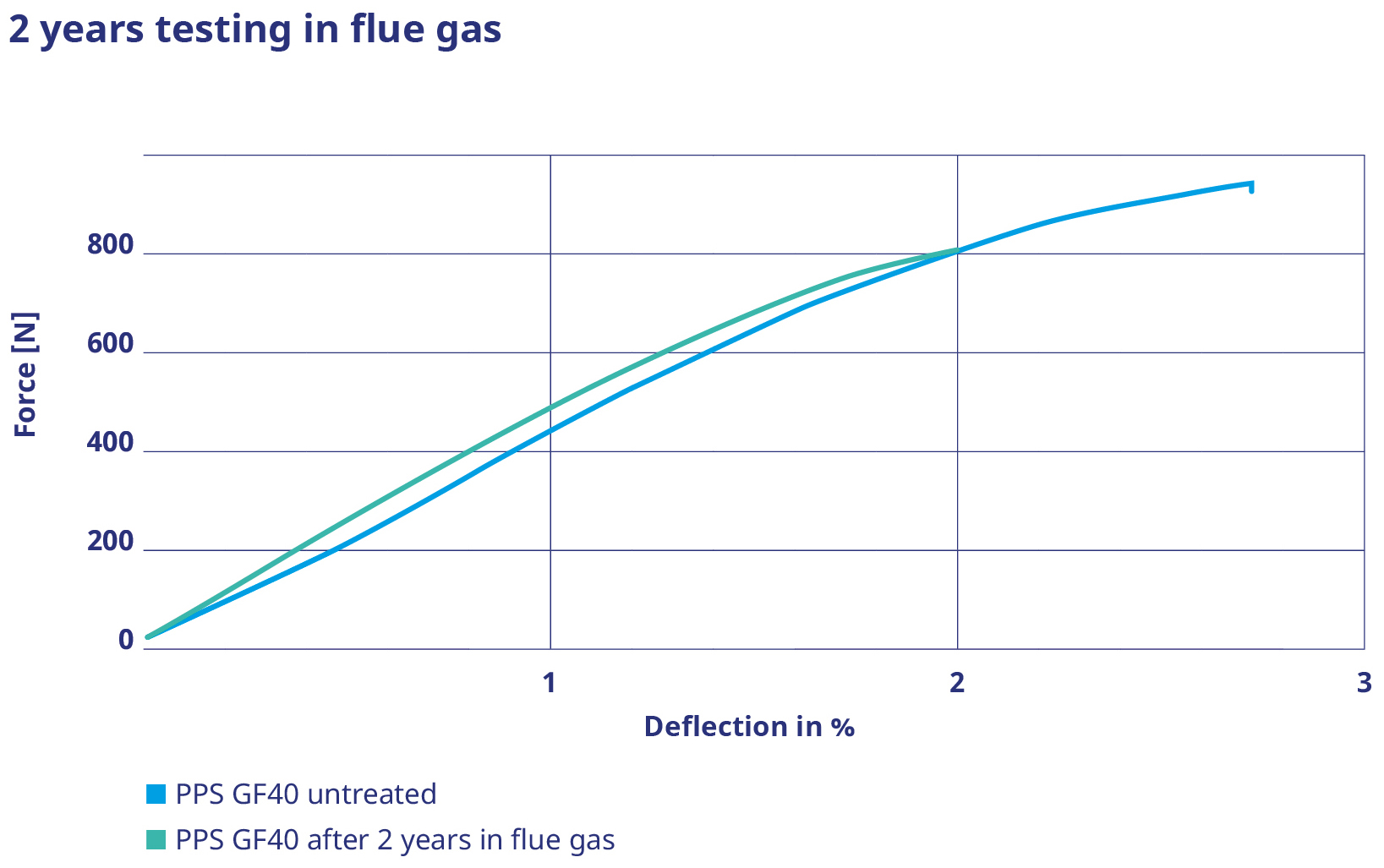

Test pieces of the various materials were placed in these locations, each featuring some deliberate surface damage. After six months of operation, Technoform checked for the first time whether there were any changes to the material. Overall, the test took more than two years in order to reflect a regular inspection period at SEF.

The result:

Polyphenylene sulfide is highly convincing in every way

Of the four materials that were tested, two were unable to withstand the mechanical demands under the long-term test: PPS graphite turned out to be too brittle, and Polyketone changed its shape, so that these two materials did not qualify for the subsequent chemical analysis. What remained were two glass-fibre reinforced materials: polyphenylene sulfide (PPS) with a glass fibre content of 40 per cent and PESU with a content of 30 per cent. The qualities that stood out in both were their high levels of mechanical, chemical and thermal resistance. Based on its lower price level and a better processing efficiency, PPS GF40 turned out to be the material of choice in the end.

Where chemical impact was concerned, PPS GF40 showed the highest resistance among all the materials involved in the long-term test.

Daniel Adolph, Head of Operations at SEF

So what's the next step?

Before Technoform produces the first PPS profiles for actual use within the plant, it still needs to test the material for physical resistance. This will mean simulating mechanical strain based on finite elements. In addition, as part of a further test at the sludge dewatering and incineration plant, various bonding methods will be tested for their chemical resistance.

Conclusion:

Solid materials are superior to coated solutions

The long-term test at SEF has shown that PPS with glass fibre is the best combination of materials for the aggressive environment at SEF. In terms of chemical resistance, polyphenylene sulfide with glass fibre ideally combines all the properties previously achieved through coatings, with the important benefit that damage to components does not have any negative effect on their performance. Maintenance and repairs, which were often necessary with coated components, should therefore be required less frequently in the future. “We’re expecting the new material to reduce the maintenance costs of our plant,” says Daniel Adolph.

What he particularly appreciates about working with Technoform is the level of trust and openness together with the expertise: “We can rely on a team of professionals who contribute lots of experience from similar projects.” Daniel Adolph also values Technoform’s flexibility: “We had a lot of requests and specific demands, to which Technoform responded flexibly.”

Whenever the demands on a material are as high as in this project, textbooks and datasheets are of no use. Instead, you need a service provider who understands all the ins and outs of the material.