Seawater Desalination: Far ahead

How high-performance polymer based materials can make water desalination clean up its act.

Water is an important part of quality of life. And it needs to be fresh, clear and pure to make it all the way to a drinking glass. This journey is longer in some parts of the world than in others – and may cause harm to the environment depending on what methods are used. Up until now, the thermal desalination of seawater has caused corrosion inhibitors, copper particles and purification agents to leach into the ocean by the tonne. A new type of polymer based tube developed by Technoform is set to change this. The miles of tubing which are used to evaporate saltwater to make drinking water are currently made from aluminium-brass, titanium or copper-nickel alloys, and are therefore prone to fouling. A polymer based tube would eliminate this problem.

The systematic trend analysis that Technoform performs in preparation for new product ideas are always leading the extrusion specialists into uncharted territory, and in this case the territory is a coast. Given the forecasts that have been made for water, one of life’s most vital resources, the company’s Innovation

Management division was quick to find potential. "Of course there were some people who warned us not to get our hopes up. Up until then, no one had managed to extrude plastic with sufficient conductive properties. So it’s a good thing that we stuck to our guns!" says Innovation Manager Jasmin Düwell.

The facts are as follows: scientists expect water shortages to become an increasingly big problem in future, resulting from global population growth and industrialisation. By 2025, roughly 1.8 billion people could be affected by water shortages and up to two thirds of the world’s population may suffer from restrictions. Seawater desalination plants are already the main source of drinking water in the Gulf States. Large-scale plants such as the Jebel Ali in Dubai, which is combined with a power station, harvest up to 500,000 cubic metres of drinking water from the sea every day. In Europe, Portugal and Spain fight for every drop of rainwater. And in drought-stricken California, 44 desalination plant projects are already being planned.

But water shortages are not the only problem. Tubing inside falling film evaporators is typically made from titanium or copper, finite raw materials that are in high demand and also very prone to corrosion. And this is where Technoform set to work: the aim was to develop an alternative of plastic with a high optimisation potential – in terms of the environment and cost savings.

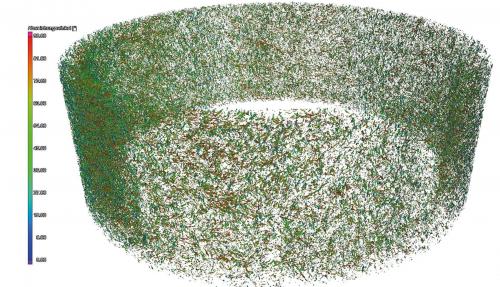

As a material, plastic beats metals hands down when it comes to corrosion resistance. Its thermal conductivity, on the other hand, is much worse. The project was worked on continuously over a period of three years by the company’s research and development team: process engineers, toolmakers and design engineers. They mixed all kinds of filler material into the thermoplastics, experimenting with various quantities, optimised the extrusion process and changed the composition of the compound again and again.

Thomas Orth, R&D Engineer

When tests were performed on the innovative plastic-graphite pipes to determine their fouling and corrosion tendencies, they scored highly, as was expected. The amount of deposits that adhere to the surface of the plastic is almost zero. This means that only a small fraction of the chemicals used to clean the plant now need to be used, and rinsed out into the ocean. The particles of the filler material are almost completely incorporated into the plastic, with the plastic effectively acting as an adhesive. And unlike copper, graphite is not harmful to the environment or human health.

Encouraged by their findings, the Technoform team went to visit the key players in the Middle East to present their innovative idea. The development engineers also wanted to find out what particular things customers might be looking for. It turned out that their main concern was the outside of the pipe, as evaporation is only fully effective if the outside is completely wetted. Another six months of testing, designing and recombining, and it was done... The Technoformers had developed a sophisticated procedure for activating the pipe’s surface, exactly as required. The inside of the pipe has hydrophobic properties, encouraging the water droplets to condense and further increasing heat transfer and the overall heat transition coefficient. On the outside, the flowing water makes full contact with the surface of the pipe.

The innovation that Technoform has developed is also unbeatable when it comes to sustainability. The total CO2 footprint of the PP-graphite pipes, taking all manufacturing steps into account, is 74% lower than that of their metal equivalent.